Precision Color Measurement for System Manufacturers

In the digital printing industry, integrated color measurement has become a key element for consistent quality and process reliability. For Original Equipment Manufacturers (OEMs), BARBIERI electronic provides a proven technology platform that can be seamlessly integrated into printers, production systems or automation lines – delivering highest accuracy and repeatability in color measurement.

Why Partner with BARBIERI

-

Proven Technology Platform – Our qb-Technology forms the technological core: a high-precision spectrophotometric engine developed over decades and fully compliant with ISO 13655.

-

Modular Integration – From compact sensor modules to fully automated inline solutions, our architecture allows flexible integration into digital printing, inkjet, and industrial coating systems.

-

Unmatched Precision – Supports reflective and transmissive measurements, variable apertures and automated calibration routines to ensure stable and consistent results across all substrates.

-

Scalable and Field-Proven – Benefit from our deep experience in large-format, textile, and packaging printing. You build the machine – we provide the measurement technology that enhances its performance.

Competitive Advantages for OEMs

-

Added Value for Your Customers – Built-in color measurement ensures process stability, repeatable color quality and minimized waste.

-

Accelerated Time-to-Market – Proven and ready-to-integrate technology reduces development risk and speeds up product introduction.

-

Flexible and Future-Proof – Designed for multiple materials, ink types and media geometries, adaptable to diverse applications and configurations.

-

Quality as a Differentiator – “Powered by BARBIERI” becomes a mark of precision and reliability in color-critical production environments.

Typical OEM Applications

-

Roll-to-roll inkjet systems using UV inks

-

Packaging and label printing lines with inline quality control

-

Flatbed printers for rigid and structured materials

-

Industrial décor and large-format applications requiring consistent color on diverse substrates

Our OEM Integration Process

- Requirement Definition – Joint analysis of your printing, media and ink systems and the intended measurement conditions.

- Technical Specification – Selection of the suitable spectrophotometer module (aperture size, measurement mode, substrate type) and interface architecture.

- Integration & Calibration – Mechanical and software integration, factory calibration and validation to ensure compliance with industry standards.

- Validation & Ongoing Support – Maintenance, and re-certification services ensure sustained accuracy and reliability.

Partner with BARBIERI

Let’s take your printing system to the next level of color precision and performance. With decades of experience in digital color measurement, BARBIERI delivers the technology foundation for your success as an OEM.

Contact us to explore your integration options – we deliver the color measurement, you deliver the machine.

BARBIERI OEM

Embedded Spectral Color Sensor ECS qb

Bring unmatched precision and reliability to your production workflow with the BARBIERI OEM Embedded Spectral Color Sensor, designed for seamless integration into your digital printing and manufacturing systems. Measure color patches in continuous measurement mode or perform spot measurements.

Next-Level Color Accuracy powered by Barbieri qb Technology

Based on BARBIERI’s proven qb spectral technology, this OEM sensor delivers outstanding spectral measurement performance for a variety of applications. It ensures that output meets the highest standards of color calibration, profiling, and process control.

OPC-UA enabled

The BARBIERI OEM Embedded Spectral Color Sensor is OPC UA enabled, ensuring seamless and standardized communication with industrial digital printing systems. This makes integration into smart factory environments straightforward, secure, and future-proof, supporting Industry 4.0 workflows and advanced process automation.

Designed for OEM Integration

The sensor is compact, robust, and tailored for printer and system manufacturers who want to integrate high-end spectral color measurement capabilities directly into their solutions.

Key Benefits & technical highlights

- Inline integration – scan speed 12 measurements per second, 15 Volt power supply Power-over Ethernet, Ethernet port – OPC-UA protocol

- Integrated Barbieri qb technology – Trusted spectral accuracy, according to ISO 13655:2017 measuring conditions M0, M1, M2 or M3 with optional Pol-Filter, 45°:0° geometry with the following features:

- Optimized for industrial environments.

- Self-calibrating with internal reference white.

- Available with following measuring apertures:

- 2 mm diameter/ min. >=6 mm color patch size

- 6 mm diameter/ min. >=10 mm color patch size

- Measuring sensor: diffraction grating with diode array

- The sensor performs measurements in contact mode

- Versatile applications – Perfect for color calibration/linearization, ICC profiling, and process stability monitoring with control strips. Reliable measurements across a wide range of media and substrates.

BARBIERI OEM

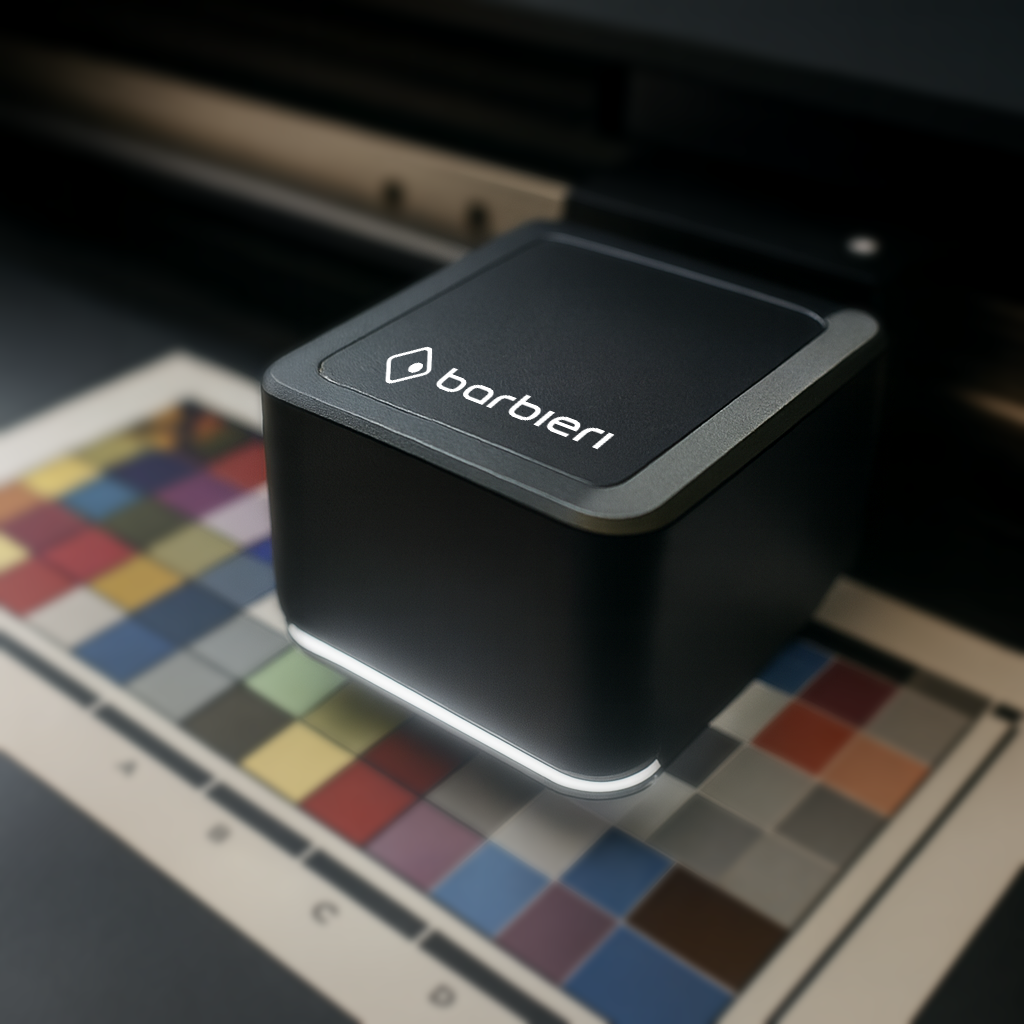

Spectro Cobot qbV

Advanced Automated Robotic Color Measurement Solution

This cutting-edge system leverages the high-precision Barbieri qb-Technology spectral sensor and advanced vision technology for color calibration and color quality control in digital printing.

Streamlined Workflow and Superior Color Consistency

Designed to meet the demands of modern digital printing, this automated solution streamlines workflows, drastically reduces the need for manual intervention, and ensures superior color consistency throughout the entire production cycle.

Powered by Barbieri qbV-Technology

At the heart of this innovative solution is the Barbieri qbV-Technology. Known for its unparalleled precision, this sensor technology integrates seamlessly with Artificial Intelligence (AI) and Machine Vision technology, providing a robust platform for fully automated color calibration and quality control processes. The integration of AI allows the system to learn and adapt, continuously improving accuracy and reliability over time.

- AI and vision systems recognize and measure Colour targets automatically

- Robotics ensure to measure large volume of color patches, precision and repeatability

- Colour data connects directly to production for real-time feedback

The components of the Spectro Cobot qbV

qb-Technology + Vision system

- Spectral Colour Sensor, (ISO 13655 conform), based on qb-Technology, to capture spectral data

- Integrated Stereo Computer Vision System to detect color charts

- Cobot control library to operate the sensor with Cobots

Scalable Industry 4.0 integration, fully developed solution by Barbieri